My initial position

Discarding is a way of maintaining the dominant system, which is the system of production. We discard to make room for new production and for the society to keep ‘growing’. It is not necessarily wrong for society to grow, but we must look at alternatives outside the dominant systems.

Initial explorations

Principal / guidelines

- Address the system not the symptom. (Liboiron and Lepawsky, 2022)

- Differentiate discard from waste – our personal experiences of discarding and recycling is drastically different from the industrial practice of discarding and recycling. (Lepawsky, 2024)

- Differentiate scale

My interests and questions

- Why do we choose certain materials to make cardboard? What are the packaging methods before cardboard? Cloth?

- Why the lifecycle last for only certain period of time (appliances used to last lifelong but now you need to replacement every few years)

- What does the post-consumption life look like for cardboard? How much energy, natural and human resources does it take to recycle or to discard cardboard?

Research on cardboard

What are the industrial process of recycling cardboard?

How is cardboard recycled? A step-by-step explanation

- Collection of cardboard from kerbside bins or businesses.

- The material is sorted into different types.

- The material is shredded and pulped.

- The pulp is filtered to remove contaminants.

- The pulp is dried and “finished” into sheets of paper again.

- Specialist equipment manufactures new cardboard material.

Chemicals used to break down cardboard into fibres: sodium hydroxide, sodium silicate, and hydrogen peroxide to break down the cardboard into fibres.

How to recycle cardboard by re-making it into paper on a domestic scale?

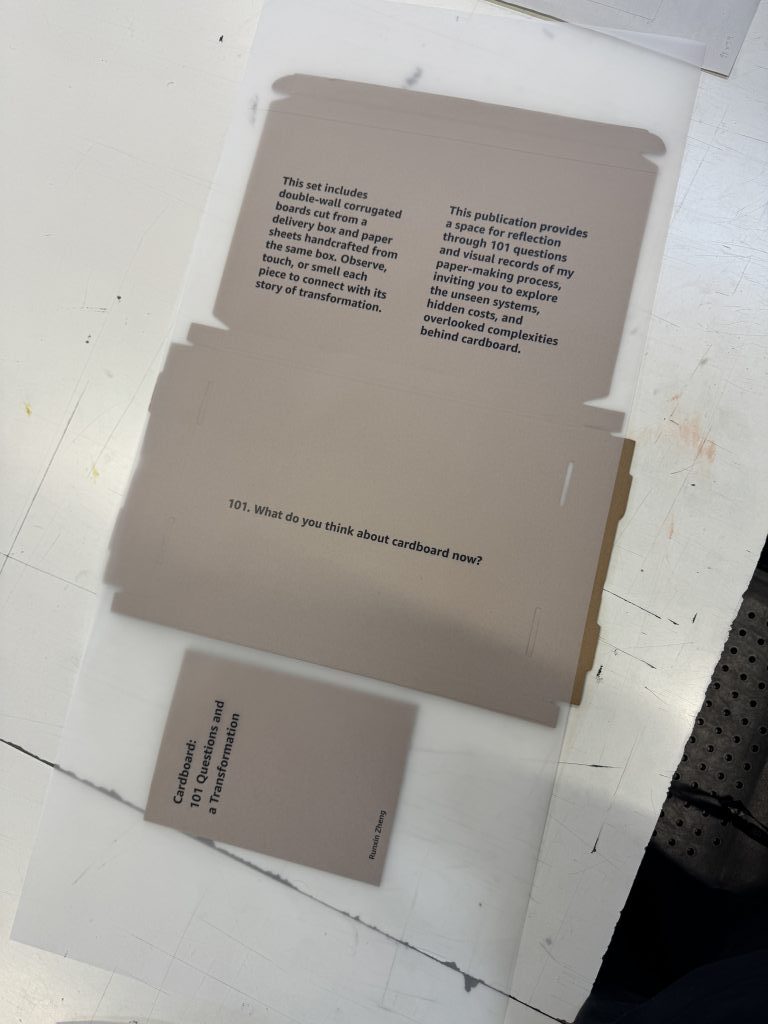

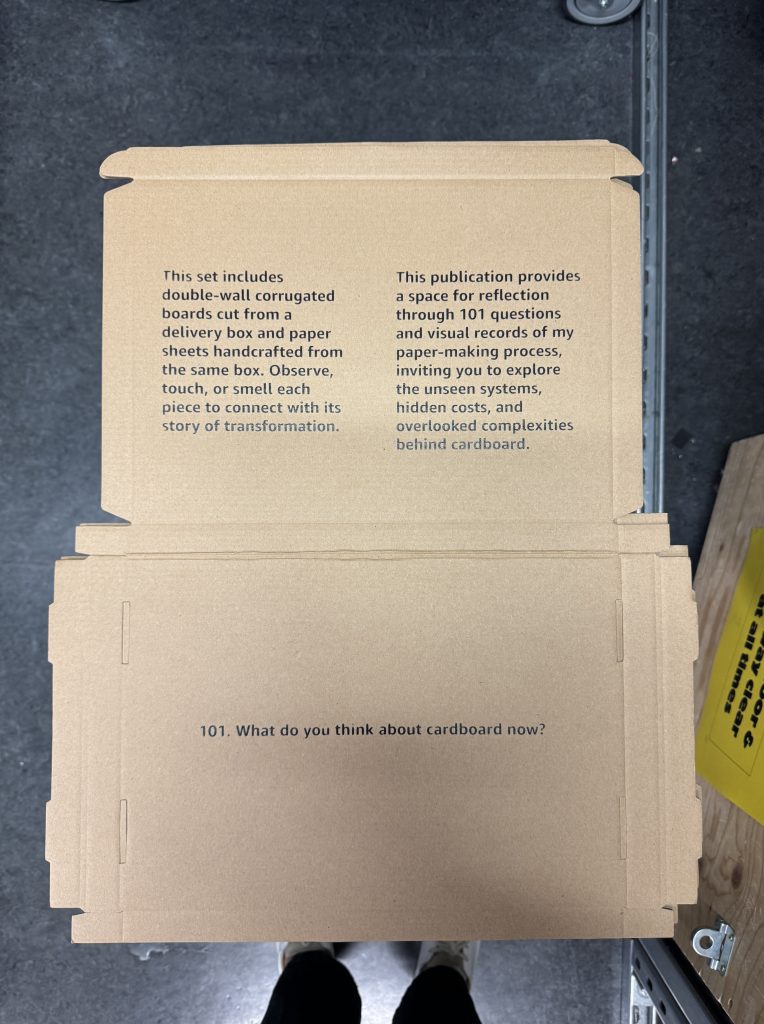

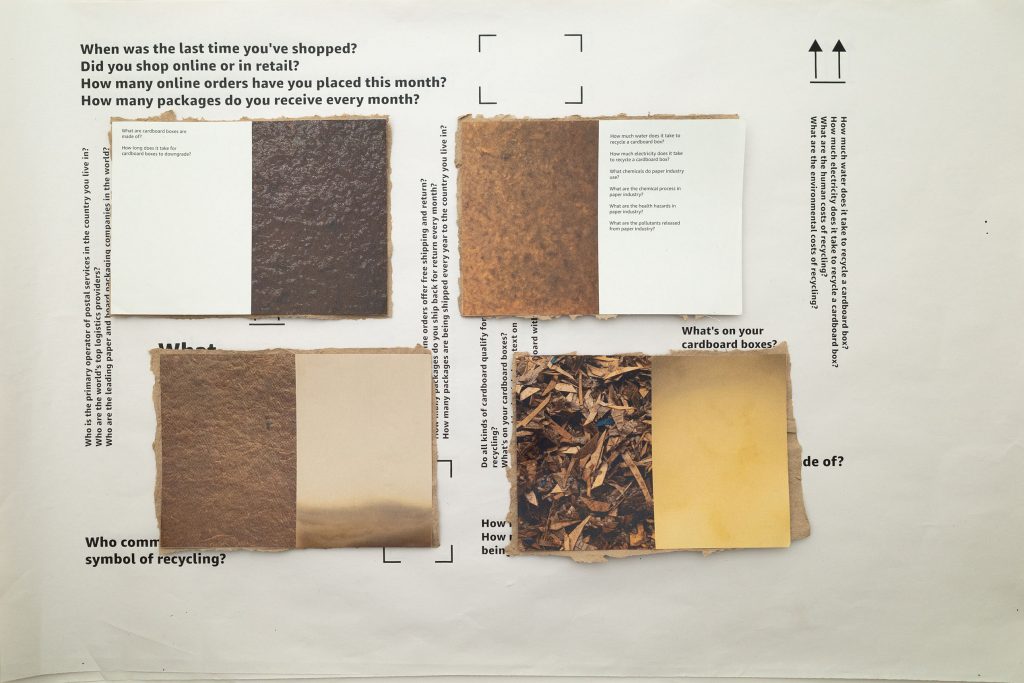

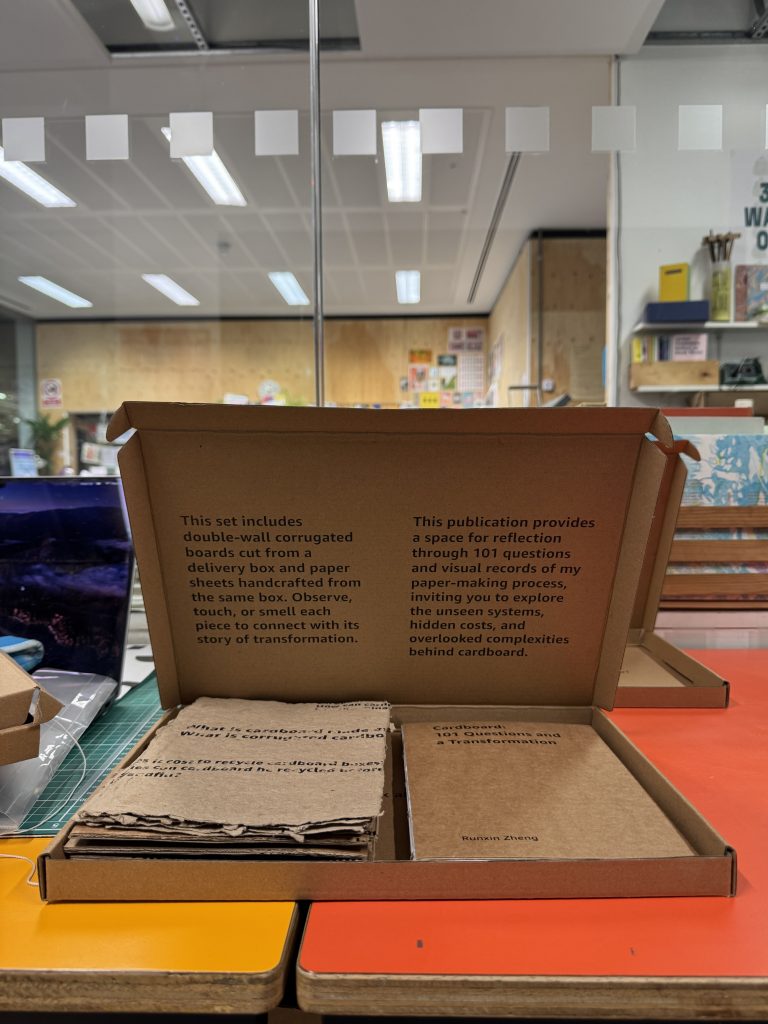

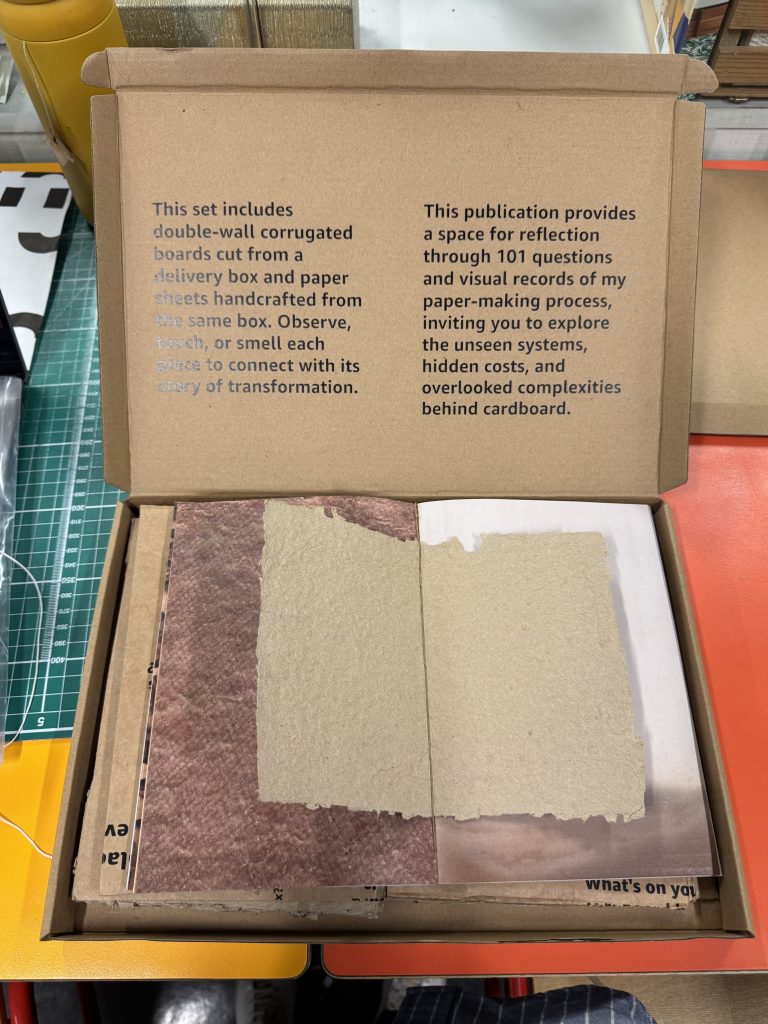

In this project, I studied the recycling process of cardboard by remaking it into paper mechanically at home, without any chemicals. During the process, I learnt that cardboard could be as problematic as other materials, like plastics, even when branded as sustainable. For instance, recycling cardboard requires significant energy and water in addition to the chemicals used to break down and sanitise the cardboard. (source) While cardboard is highly recyclable, many people do not know how to recycle it properly, and when it’s recycled, it can only be recycled a limited number of times before being sent to a landfill. The production volume of cardboard has increased yearly, which begs the question – is recycling working, or is it a reputation-building tool, validating the production of materials? Is there any other alternative to recycling and producing more cardboard boxes? The system remains vague and fragmented even after my practice-based attempts to understand it. I still don’t have all the answers to my questions. However, questioning could be a way to narrate and experience systems.

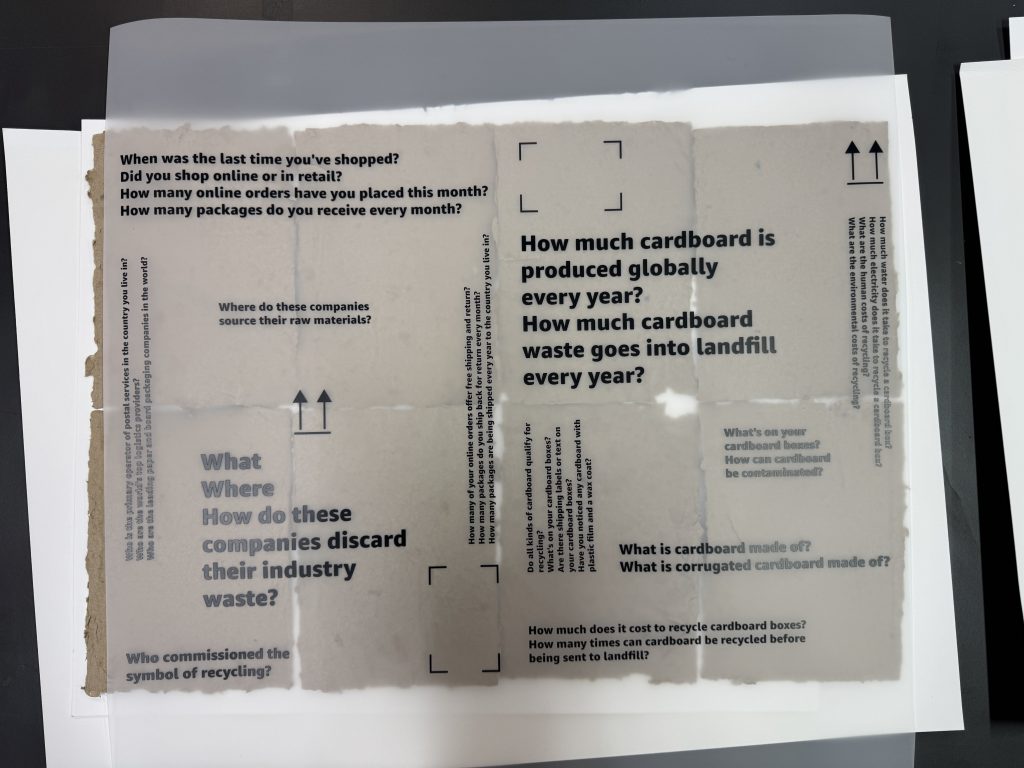

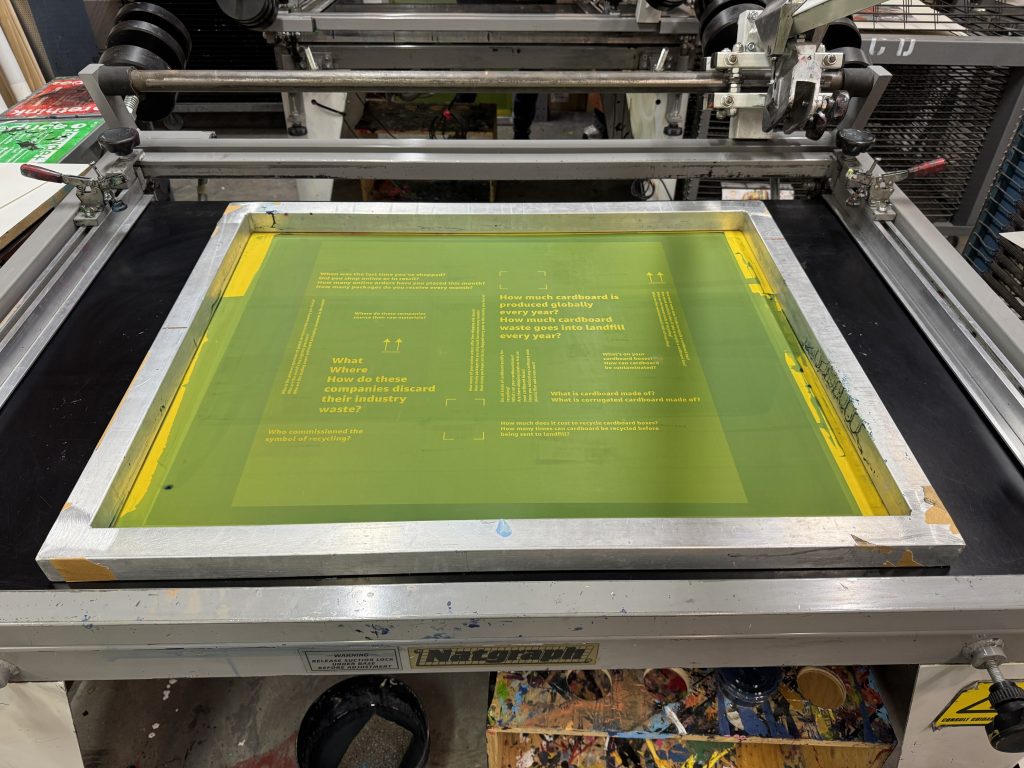

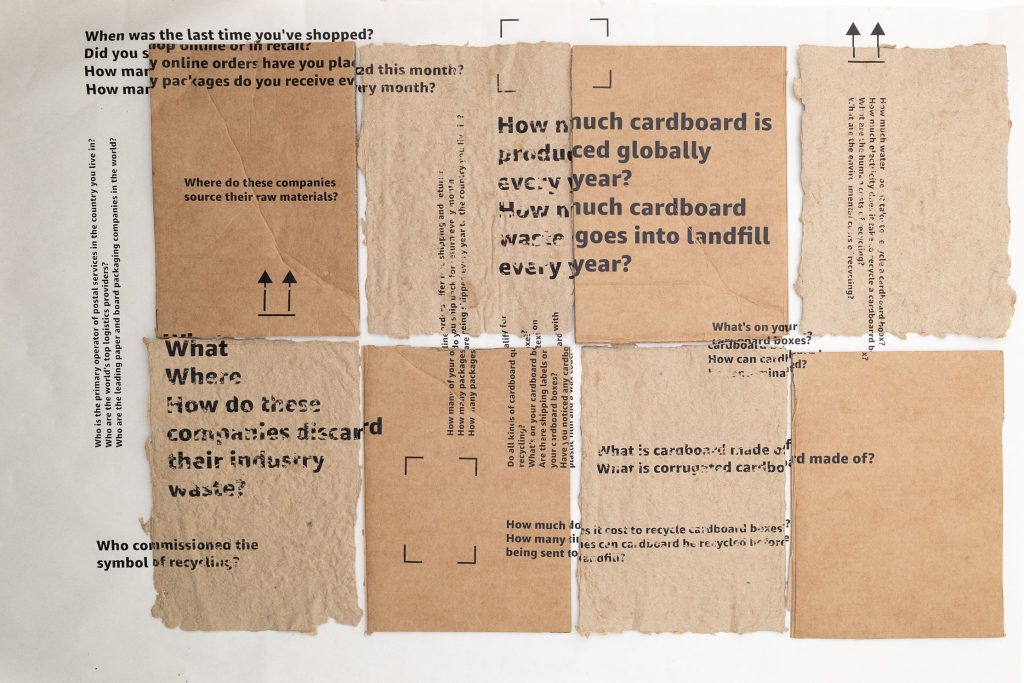

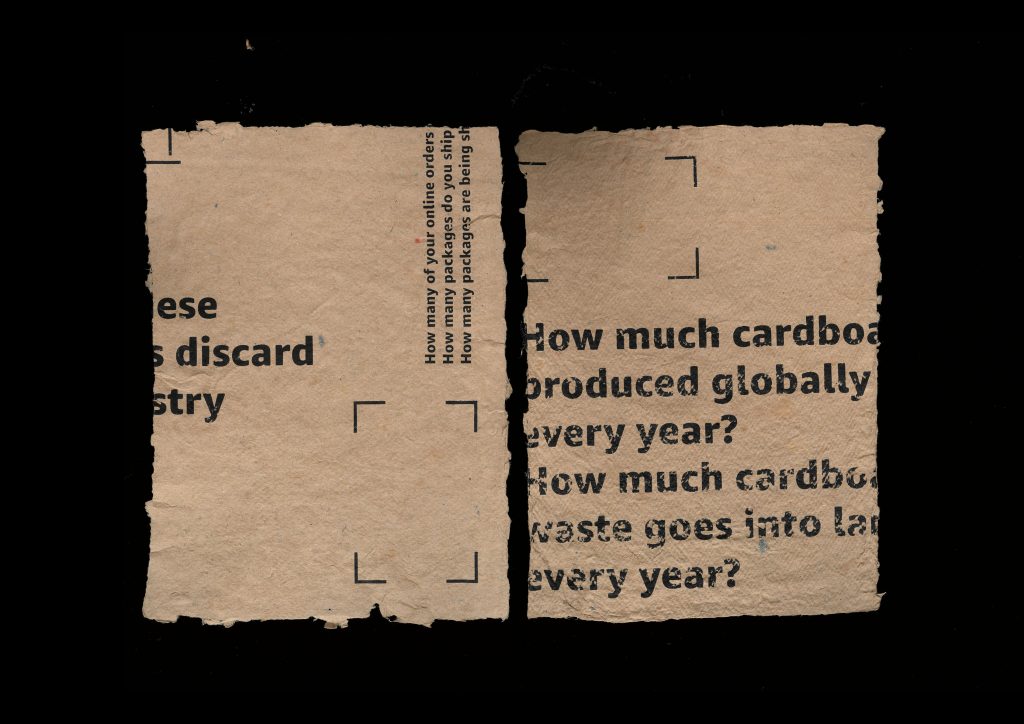

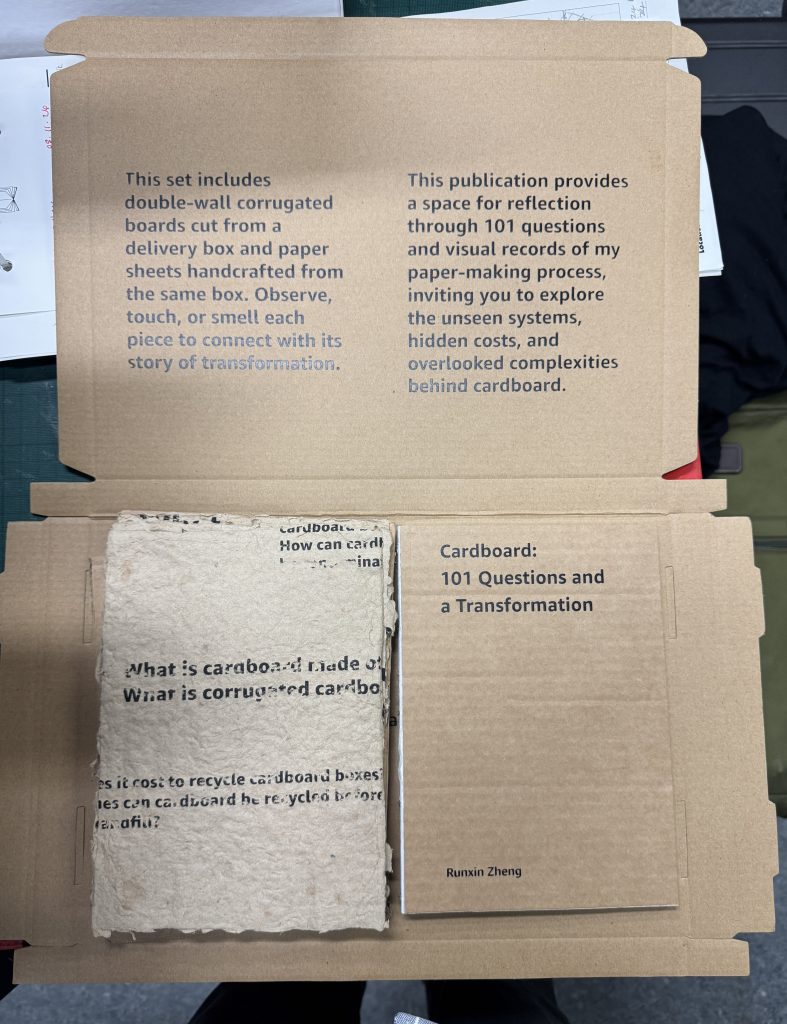

Screen Printing

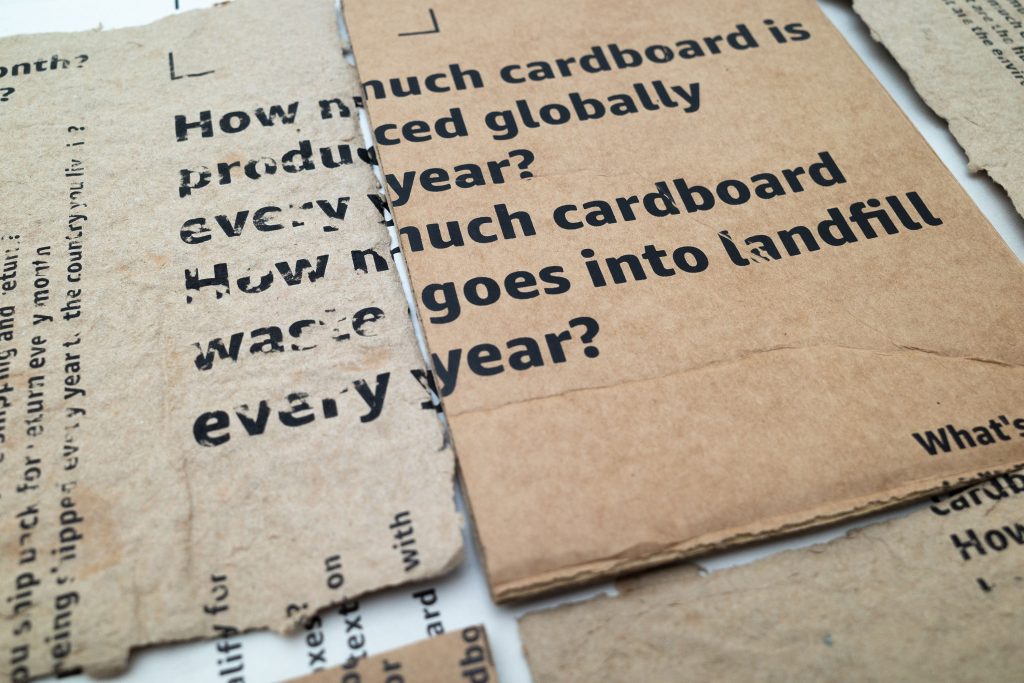

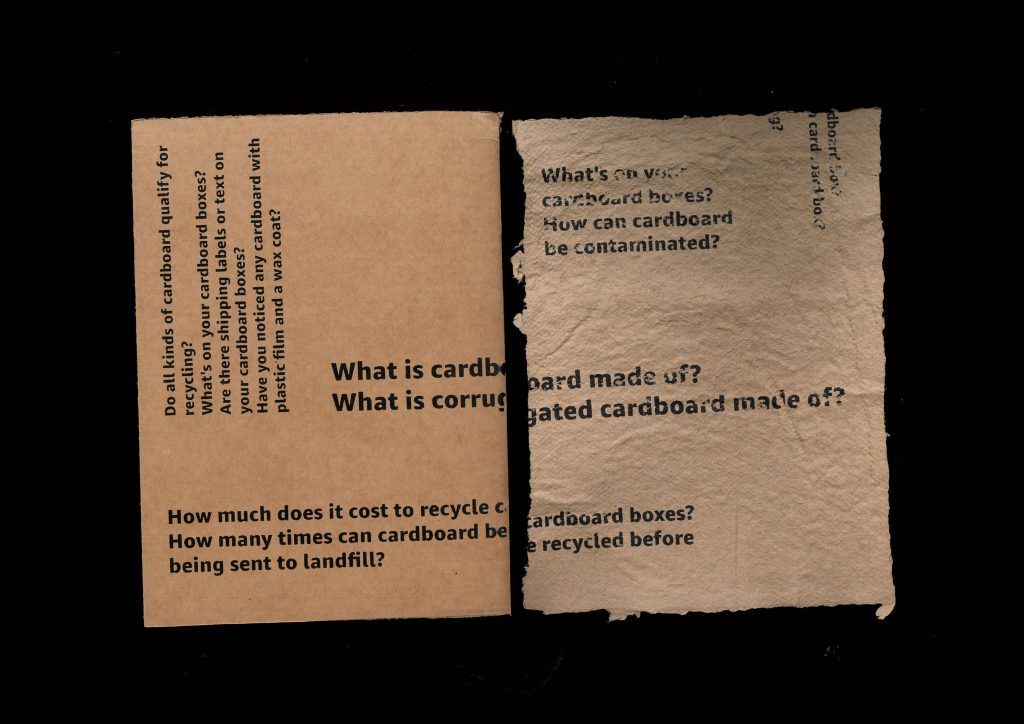

The production method must mirror the system I critique. Many packaging companies adopt silkscreen printing to print messages on cardboard. I used screen print to lay my questions on handmade cardboard paper and regular corrugated cardboard. After examining the recycling process of cardboard, I realised that cardboard is often cut or folded into smaller pieces and put into a cubicle bile. As a result, the messages printed on cardboard are often cut off as well. These fragments reflect how we approach the system, never in its entirety, but only piecemeal. Therefore, my questions are also printed across several A5 pieces of paper, then separated and put into a pile. To read the complete questions, the readers may need to piece the paper together like a puzzle. Yet the complete message might never be recovered as letters fall through the cracks between papers during printing, which I consider a metaphor for recycling. There is always something unseen, lost in the process.

To deepen my understanding of cardboard’s materiality, I examined its properties, including labels, text, layout, and printing techniques, many of which use silkscreen printing. While commercial cardboard is often printed with industrial screen-printing as part of an automated manufacturing process, my access was limited to a workshop equipped only with manual screen-printing tools. In the next step, I screen printed selected questions onto both recycled paper and corrugated cardboard sheets, distributing the text across multiple pages, each carrying part of the message.

This production method has mirrored the scale of our encounters with systems as individuals, which is always partial, never in its entirety. The audience may need to piece the paper together like a puzzle to decipher the complete questions. Yet the full message might never be recovered as letters are omitted in the gaps between sheets of paper during printing. I considered these missing letters a metaphor for spillage, unseen costs, byproducts, or any externalities not accounted for in the recycling process and system of production. At an individual level, we rarely see the full scope of these impacts.

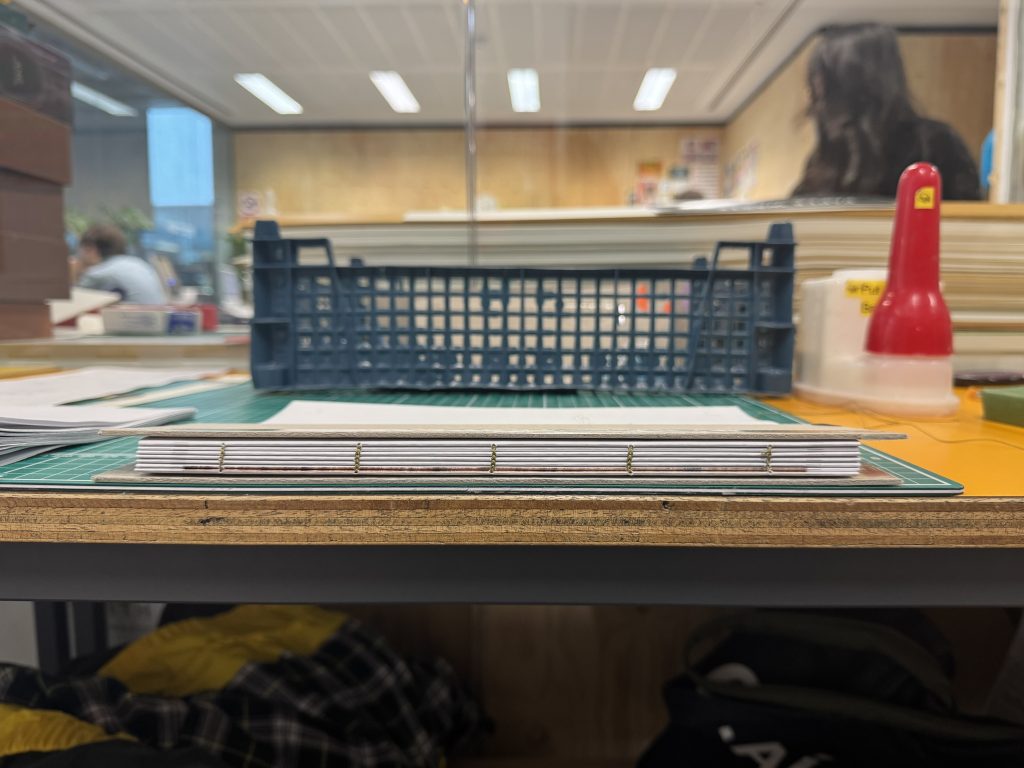

Bind and box

Behind the scene

References

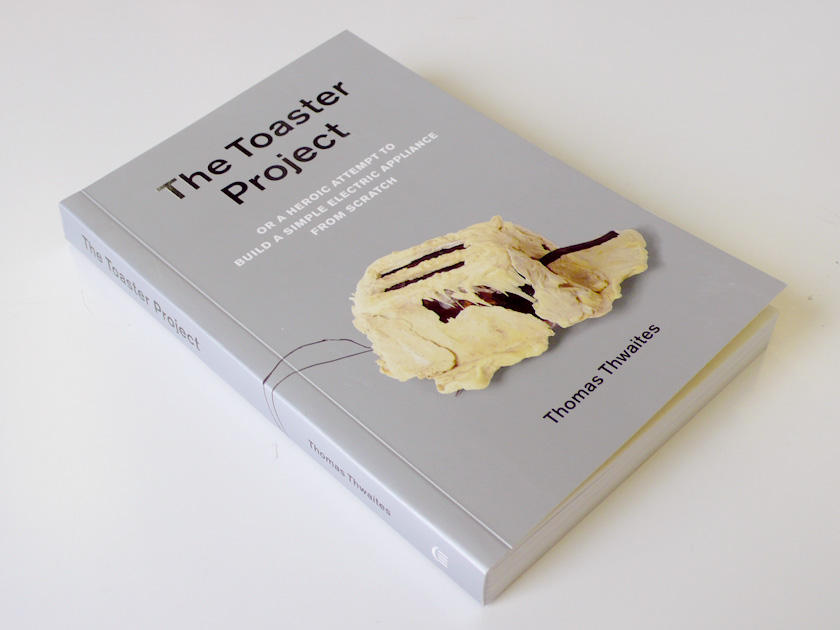

In the Toaster Project, Thwaites (2011) dismantled an electric toaster from Argos and constructed a duplicate by making all its constituent parts from scratch, revealing its underlying systems.

During the process, Thwaites also realised that no one could make a toaster from the ground up, even though he made some epic attempts, such as travelling to some of the most remote mines in the United Kingdom and extracting metals from their mineral ore. The Toaster Project was never just about the toaster. Any everyday objects, even the simplest items, can offer us insights into human society when examined rigorously and deeply. (Dyer, Deakin) Each of Thwaites’s challenges in the Toaster Project represented various systems we’ve taken for granted, from transportation to communication to production.

Further references

Deakin, N. and Dyer, J. (2022) Graphic events: a realist account of graphic design. Eindhoven: Onomatopee.

Lepawsky, J. (2024) Interviewed by R. Zheng, 17 September.

Liboiron, M. and Lepawsky, J. (2022) Discard studies: wasting, systems, and power. Cambridge, Massachusetts: The MIT Press. Available at: https://search-ebscohost-com.arts.idm.oclc.org/login.aspx?direct=true&db=nlebk&AN=2955243&site=ehost-live&scope=site (Accessed: 28 April 2024).

Thwaites, T. (2011) The toaster project : or a heroic attempt to build a simple electric appliance from scratch. New York : Princeton Architectural Press.

Voss, G. (2024) Systems ultra : making sense of technology in a complex world. London : Verso.